Monthly Archives: March 2023

SP PAC-SEAL – AKOKEN PTFE Rotary Shaft Seal

AKOKEN PTFE Rotary Shaft Seal: High-Performance Sealing Solution for Demanding Environments

As a leading supplier of sealing solutions, SP PAC-SEAL SDN. BHD. is proud to offer the AKOKEN PTFE rotary shaft seal, an advanced sealing solution designed for use in demanding industrial environments. With its exceptional chemical resistance, low friction, and high-temperature tolerance, the AKOKEN PTFE rotary shaft seal is an ideal solution for sealing applications where high-performance and durability are required.

Attributes of AKOKEN PTFE Rotary Shaft Seal:

The AKOKEN PTFE rotary shaft seal is made of high-quality polytetrafluoroethylene (PTFE), a synthetic fluoropolymer material that is known for its excellent chemical resistance, low friction, and high-temperature tolerance. This makes the AKOKEN PTFE rotary shaft seal ideal for use in applications where high temperatures and aggressive chemicals are present.

Temperature and Pressure Tolerance:

The AKOKEN PTFE rotary shaft seal can withstand temperatures ranging from -200°C to +260°C, making it suitable for use in extreme temperature conditions. It can also withstand pressures of up to 6 bar, making it a reliable sealing solution for high-pressure applications.

Functions of Single Lip, Dual Lips, and Triple Lipped:

The AKOKEN PTFE rotary shaft seal is available in three different configurations: single lip, dual lips, and triple-lipped. The single-lip configuration is suitable for low-pressure applications, while the dual-lip and triple-lip configurations provide additional sealing capabilities and are ideal for high-pressure applications.

Advantages of AKOKEN PTFE Rotary Shaft Seal:

The AKOKEN PTFE rotary shaft seal offers several advantages over other sealing solutions. It provides excellent chemical resistance, low friction, and high-temperature tolerance, making it suitable for use in a wide range of industrial applications. It is also highly durable and can withstand high pressures and extreme temperatures, making it a reliable sealing solution for demanding environments.

Usage Areas:

The AKOKEN PTFE rotary shaft seal is suitable for use in a wide range of industrial applications, including chemical processing, food and beverage production, pharmaceutical manufacturing, and many others. It can be used in both static and dynamic sealing applications, and is often used in conjunction with other sealing materials, such as elastomers, to provide additional sealing capabilities.

Installation of AKOKEN PTFE Rotary Shaft Seal:

The AKOKEN PTFE rotary shaft seal is easy to install and can be used with a variety of shaft sizes and configurations. It should be installed with a proper lubrication system and should be checked regularly for signs of wear and tear.

In conclusion, the AKOKEN PTFE rotary shaft seal is a high-performance sealing solution designed for use in demanding industrial environments. With its exceptional chemical resistance, low friction, and high-temperature tolerance, it is an ideal solution for sealing applications where high-performance and durability are required. If you’re looking for a reliable sealing solution for your industrial application, the AKOKEN PTFE rotary shaft seal is an excellent choice.

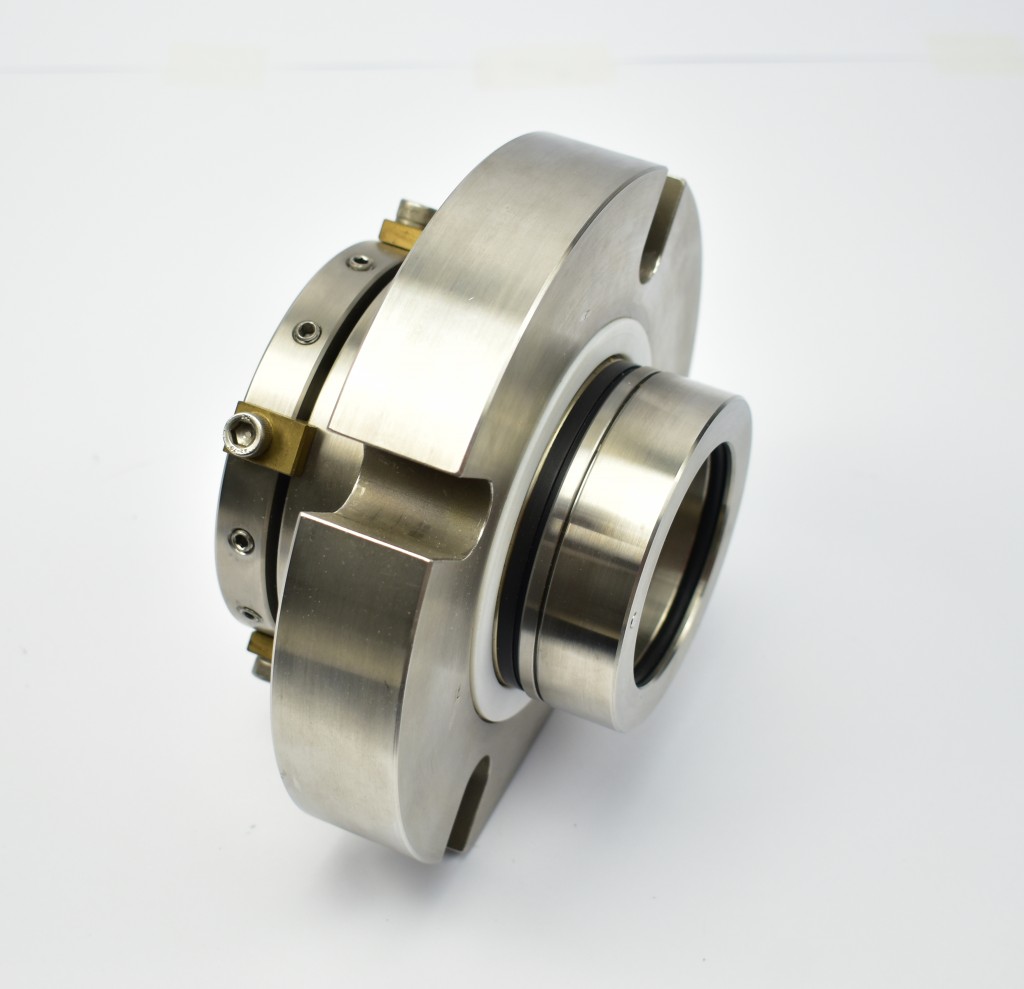

Advantages of Cartridge Mechanical Seals by SP PAC-SEAL SDN. BHD.

Mechanical seals are an important component of many industrial machines, particularly those that require the transfer of fluids. They are used to seal the gap between rotating and stationary parts, preventing the escape of fluids and the entry of contaminants. Cartridge mechanical seals are a type of mechanical seal that are increasingly becoming popular in many industries, including oil and gas, chemical processing, food and beverage, and pharmaceuticals. In this article, we will discuss the advantages of cartridge mechanical seals and how they can benefit your business.

Easy Installation and Maintenance

One of the biggest advantages of cartridge mechanical seals is their ease of installation and maintenance. Unlike traditional mechanical seals, which require skilled technicians to install and maintain, cartridge seals are designed to be easy to install and remove. This makes them ideal for industries where downtime can be costly. Cartridge mechanical seals are also designed to be easily replaced, reducing maintenance costs and improving machine uptime.

Improved Seal Performance

Cartridge mechanical seals are designed to provide superior sealing performance compared to traditional mechanical seals. They are designed to be self-aligning, which ensures that the seal faces are always in perfect alignment. This improves sealing performance, reduces wear on the seal faces, and extends the life of the mechanical seal. Cartridge mechanical seals are also designed to provide better sealing performance in high-pressure and high-temperature applications, making them ideal for use in industries where harsh conditions are common.

Reduced Seal Failure

Cartridge mechanical seals are designed to reduce the likelihood of seal failure. They are designed with a barrier fluid that provides a secondary seal to prevent the escape of process fluid. This reduces the risk of leakage and contamination, which can lead to costly downtime and damage to equipment. Cartridge mechanical seals are also designed with an axial movement feature that allows for greater flexibility in machine operation, reducing the risk of seal failure due to misalignment or vibration.

Cost-Effective

Cartridge mechanical seals are a cost-effective solution for many industrial applications. They are designed to be easily replaced, reducing maintenance costs and improving machine uptime. They are also designed to provide superior sealing performance, reducing the risk of costly downtime due to seal failure. Additionally, cartridge mechanical seals are designed to be more energy-efficient than traditional mechanical seals, which can result in significant cost savings over the long term.

In conclusion, cartridge mechanical seals offer many advantages over traditional mechanical seals, including easy installation and maintenance, improved sealing performance, reduced seal failure, and cost-effectiveness. If you are looking for a reliable and efficient mechanical seal solution for your industrial application, consider using cartridge mechanical seals from SP PAC-SEAL SDN. BHD. With our superior design and performance, we can help you improve machine uptime, reduce maintenance costs, and achieve greater productivity.

DIY Pump Servicing

Shown picture above is a typical house-hold water pump. It consists of the impeller section, the motor, and a pressure controller.

When there is a leak in-between the impeller section and the motor, it usually means your mechanical seal has worn out and in need of replacement.

If there is uncontrolled leakage from the pressure controller. It usually means the diaphragm of the pressure controller has reached its life cycle, and needs to be replaced.

As you can see DIY Pump Servicing is easy.

For more pump servicing information, do not hesitate to contact us at SP PAC-SEAL- 012 3310342.

Installation of Glass Lined Mechanical Seal for Agitator

The picture above shown is the top of an agitator. While there are blades contained in the agitator. There are mechanisms that helps to turn the blades. As shown, there is a high powered motor mounted on top and coupled with the blade’s shaft. In the middle sits a glass lined mechanical seal, hugging the shaft and sealing the agitator, preventing gases from leaking outwards.

SP PAC-SEAL Installation of Glass Lined Mechanical Seal for Agitator will be described as follows.

Before starting the replacements like everything else, preparation is highly scrutinized. The correct size of mechanical seal must be ready on-site. Due to the size of this agitator, an overhead crane is necessary to proceed with maintenance or replacement works. Also for this design of agitator, two C- spanner of the correct size are required. Other tools such as an electric nut driver comes in handy.

Once preparations are done, work shall commence. The cables connecting to the electric motor are disconnected and tied away safely.

Next is the removal of coupling between shaft and electric motor. Once the coupling is removed, the electric motor shall be secured to a crane, before loosening the nuts of gearbox to the housing. The electric motor and gearbox is lifted away together and set aside.

Upon removing the motor and gearbox, the shaft shall be secured with a crane on the top end, while the bottom end of the shaft shall have soft cloth or leather to prevent the shaft from damaging the interior of the agitator. After securing both ends, the mechanical seal usually has a setting stopper to secure it before loosening for removal. Once the settings are placed back in and secured, the C-spanner is then used to open the nut locked to the shaft and supporting it at the housing.

Bare in mind, once the nut is loosen, the shaft may drop downwards. After the nut is removed, the shaft is let down slowly, until touching the bottom. The securing of shaft can then be released. Remove the housing would give much needed space to then remove the mechanical seal.

The procedure is then reversed with a new mechanical seal installed.