Monthly Archives: April 2023

Genuity of ROTEN mechanical seal

In this age of mass production having multiple variations of the same product is inevitable. However, there are a few tell-tale signs to determine if the product that you paid a premium for is of the highest quality, correct specification and from a genuine manufacturer.

How to determine Genuity of ROTEN mechanical seal?

- The picture above shows the comparison of two mechanical seals. One is an imitation of the original ROTEN brand. If your guess is correct, the mechanical seal on the left is the imitation of ROTEN. The stamp is probably laser marked onto and out of standard.

- The surface roughness of the mechanical seal’s metal part is far from satisfactory compared to the degree of tolerance set by ROTEN, it is visible even to the naked eye. The original ROTEN has a smooth surface enabling it to reflect light, appearing shiny.

Getting the original ROTEN mechanical seal means you are guaranteed in the quality as specified. You save money by not getting a product that is prone to fail at most uncertain times.

Do share with us your experiences of using our products, should there be any sectors that we can improve.

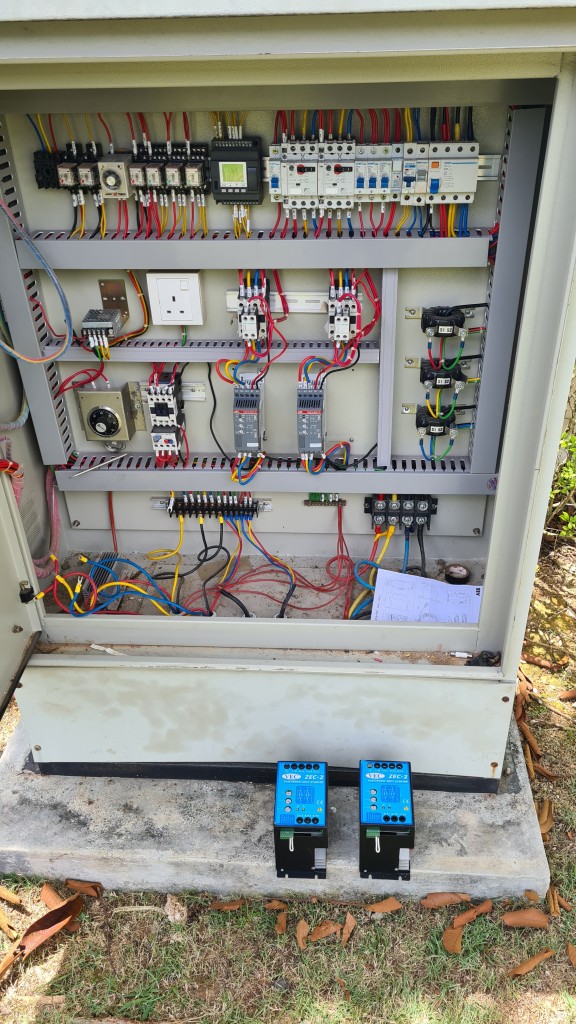

Soft Starter and It’s role in a Pump Control Panel

Soft starters are devices that are used to control the starting and stopping of electric motors. They are widely used in a variety of applications, including pumps, compressors, and fans, among others. Soft starters are different from variable frequency drives (VFDs) in that they only control the starting and stopping of the motor, whereas VFDs can also control the speed of the motor.

One of the primary advantages of using a soft starter over a VFD is that soft starters are often more cost-effective. They are also simpler to install and require less maintenance than VFDs, making them an ideal choice for applications where precise speed control is not required.

When it comes to controlling water pumps, soft starters are often the preferred option due to their ability to reduce the initial current surge that occurs when the motor is started. This current surge can cause damage to the motor and other electrical components, and can also result in high energy consumption. By reducing the current surge, soft starters can help extend the life of the motor and reduce energy costs.

If you are currently using a control panel that does not have a soft starter, it is highly recommended that you upgrade to one. By doing so, you can enjoy a number of benefits, including reduced energy consumption, increased motor life, and improved system reliability. Additionally, many soft starters come with built-in protections that can help prevent damage to the motor and other electrical components.

One of the advantages of using a soft starter in a control panel is that it eliminates the need for a transformer for isolation. Soft starters are designed to operate without the need for a transformer, which can simplify the control panel design and reduce the overall cost.

In traditional control panel designs, a transformer is often used to isolate the control circuit from the power circuit. This is done to protect the control circuit from high voltage or current spikes that can occur in the power circuit. However, using a transformer can add complexity to the control panel design and increase the overall cost of the system.

By using a soft starter in the control panel, you can eliminate the need for a transformer and simplify the design. Soft starters are designed to provide the necessary isolation and protection for the control circuit, without the need for a separate transformer. This can help reduce the size and cost of the control panel, while also improving the overall reliability of the system.

In addition to eliminating the need for a transformer, soft starters also offer other benefits for control panel design. They can reduce the amount of wiring required, as they typically only require a few connections to be made. They can also be easily integrated into existing control systems, making them a flexible and adaptable solution for a wide range of applications.

Overall, using a soft starter in a control panel can simplify the design, reduce costs, and improve the reliability of the system. If you are considering upgrading your control panel for a water pump or other electric motor, it’s worth considering the benefits of using a soft starter.

Why Originality matters for Mechanical Seals

The Importance of Originality for ROTEN Mechanical Seals

Mechanical seals are essential components of industrial equipment, providing a barrier between the process fluid and the surrounding environment. To ensure optimal performance and safety, it is crucial to use original mechanical seals that are designed and manufactured to meet specific requirements and specifications.

When it comes to mechanical seals, the ROTEN brand stands out as a leader in originality and quality. ROTEN has been designing and producing mechanical seals for over 40 years, and their products are widely recognized for their high level of reliability, efficiency, and safety.

Originality is a hallmark of the ROTEN brand. Each ROTEN mechanical seal is designed and manufactured to meet specific requirements and specifications, ensuring that it will perform reliably and efficiently in its intended application. The company invests heavily in research and development, using the latest technology and materials to create innovative and reliable sealing solutions.

ROTTEN mechanical seals are made from high-quality materials and undergo rigorous testing to ensure that they meet or exceed industry standards for performance and safety. The company has a strong commitment to quality control and inspection, with every seal subject to stringent testing before it leaves the factory.

Using original ROTEN mechanical seals offers several benefits. First and foremost, it ensures that the equipment will perform as expected, providing reliable and efficient operation. Original seals are also backed by warranties and guarantees, which are only valid for original products. This can provide peace of mind and protection against costly downtime or equipment failures.

In addition to the benefits of using original mechanical seals, there are also potential risks associated with using counterfeit or imitation seals. Non-original seals may be made from lower-quality materials, and may not undergo the same level of testing, which can compromise their performance and safety. Using counterfeit or imitation seals can also void warranties and guarantees, putting equipment at risk.

In summary, using original ROTEN mechanical seals is crucial for ensuring reliable and efficient equipment operation, and for protecting against potential risks associated with non-original seals. ROTEN’s commitment to originality and quality make their products a top choice for industrial equipment applications. By choosing ROTEN mechanical seals, businesses can ensure that their equipment operates at peak performance, while minimizing risks and protecting investments.

Why ROTEN Mechanical Seals

ROTEN Mechanical Seals: A Reliable and Versatile Sealing Solution

Mechanical seals play a crucial role in ensuring the reliable and efficient operation of various industrial equipment, such as pumps, mixers, and agitators. One of the leading manufacturers of mechanical seals is ROTEN, a company that has been providing sealing solutions for over 40 years.

ROTEN was founded in 1978 in Italy and has since grown to become a global leader in the mechanical seals industry. The company has a strong commitment to research and development, investing heavily in the latest technology to create innovative and reliable sealing solutions.

ROTEN’s products are used in a wide range of industries, including chemical, petrochemical, pharmaceutical, food and beverage, and water treatment. The company’s success is built on a reputation for providing high-quality, cost-effective, and reliable mechanical seals that meet the specific needs of its customers.

Materials Used in ROTEN Mechanical Seals

ROTEN uses a variety of materials in the production of its mechanical seals, depending on the application and requirements of the customer. Some of the most commonly used materials include:

- Silicon Carbide: a hard and durable material that is ideal for applications involving high temperatures and abrasive fluids.

- Tungsten Carbide: a material that is highly resistant to wear and corrosion, making it suitable for applications involving abrasive fluids.

- Carbon: a material that is highly resistant to chemical attack and can withstand high temperatures.

- Stainless Steel: a material that is strong and durable, making it ideal for applications that require high pressure and temperature.

Versatility of ROTEN Mechanical Seals

One of the key features of ROTEN mechanical seals is their versatility. The company offers a wide range of mechanical seals, including:

- Single Mechanical Seals: used in applications where the seal faces are in contact with the process fluid.

- Double Mechanical Seals: used in applications where a high level of sealing is required, such as those involving hazardous or toxic fluids.

- Cartridge Seals: designed for easy installation and maintenance, making them ideal for applications where downtime must be kept to a minimum.

- Split Seals: designed for use in large equipment, such as mixers and agitators, where traditional seals would be difficult to install and maintain.

Conclusion

ROTEN mechanical seals are a reliable and versatile sealing solution for various industrial applications. With a commitment to research and development and a reputation for providing high-quality and cost-effective solutions, ROTEN has become a global leader in the mechanical seals industry. Whether you require a single mechanical seal, double mechanical seal, cartridge seal, or split seal, ROTEN has a product that will meet your needs. As the sole agent for ROTEN mechanical seals, SP PAC-SEAL is well-positioned to provide customers with the best possible sealing solutions.