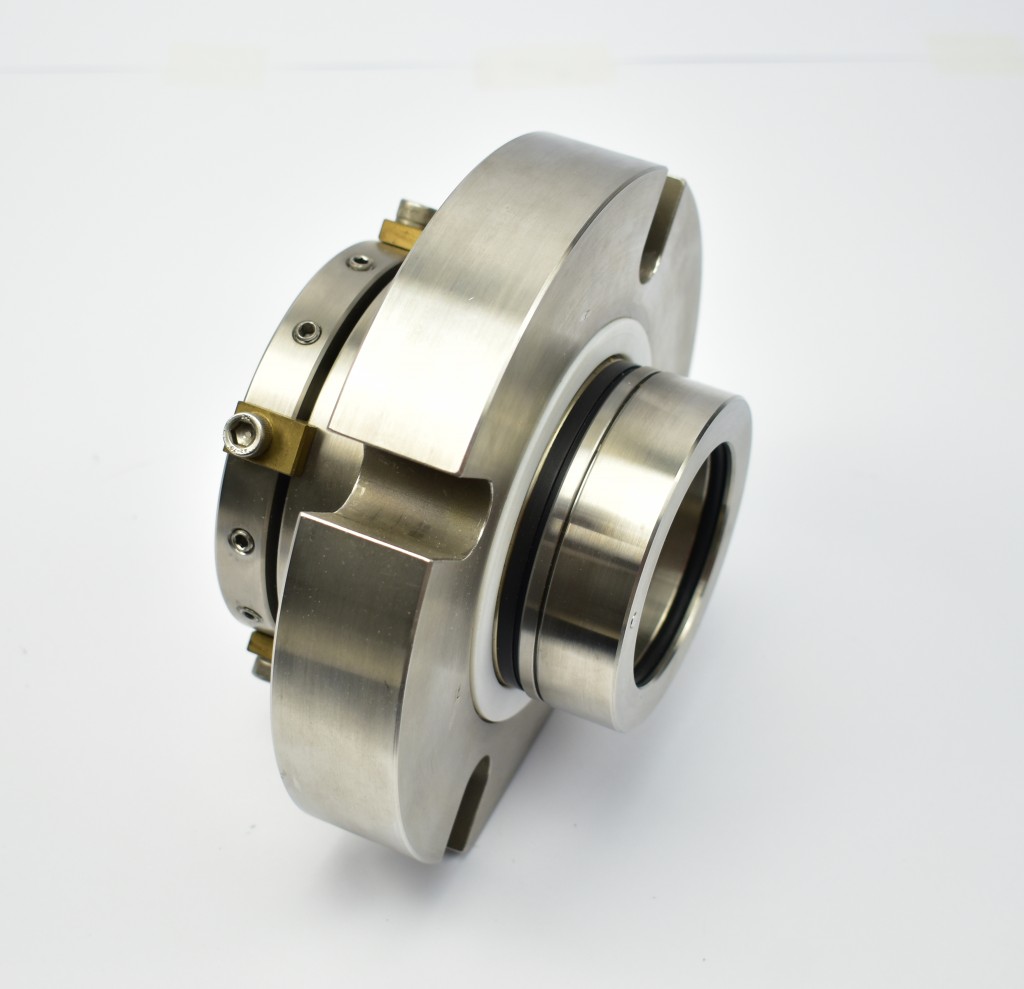

Advantages of Cartridge Mechanical Seals by SP PAC-SEAL SDN. BHD.

Mechanical seals are an important component of many industrial machines, particularly those that require the transfer of fluids. They are used to seal the gap between rotating and stationary parts, preventing the escape of fluids and the entry of contaminants. Cartridge mechanical seals are a type of mechanical seal that are increasingly becoming popular in many industries, including oil and gas, chemical processing, food and beverage, and pharmaceuticals. In this article, we will discuss the advantages of cartridge mechanical seals and how they can benefit your business.

Easy Installation and Maintenance

One of the biggest advantages of cartridge mechanical seals is their ease of installation and maintenance. Unlike traditional mechanical seals, which require skilled technicians to install and maintain, cartridge seals are designed to be easy to install and remove. This makes them ideal for industries where downtime can be costly. Cartridge mechanical seals are also designed to be easily replaced, reducing maintenance costs and improving machine uptime.

Improved Seal Performance

Cartridge mechanical seals are designed to provide superior sealing performance compared to traditional mechanical seals. They are designed to be self-aligning, which ensures that the seal faces are always in perfect alignment. This improves sealing performance, reduces wear on the seal faces, and extends the life of the mechanical seal. Cartridge mechanical seals are also designed to provide better sealing performance in high-pressure and high-temperature applications, making them ideal for use in industries where harsh conditions are common.

Reduced Seal Failure

Cartridge mechanical seals are designed to reduce the likelihood of seal failure. They are designed with a barrier fluid that provides a secondary seal to prevent the escape of process fluid. This reduces the risk of leakage and contamination, which can lead to costly downtime and damage to equipment. Cartridge mechanical seals are also designed with an axial movement feature that allows for greater flexibility in machine operation, reducing the risk of seal failure due to misalignment or vibration.

Cost-Effective

Cartridge mechanical seals are a cost-effective solution for many industrial applications. They are designed to be easily replaced, reducing maintenance costs and improving machine uptime. They are also designed to provide superior sealing performance, reducing the risk of costly downtime due to seal failure. Additionally, cartridge mechanical seals are designed to be more energy-efficient than traditional mechanical seals, which can result in significant cost savings over the long term.

In conclusion, cartridge mechanical seals offer many advantages over traditional mechanical seals, including easy installation and maintenance, improved sealing performance, reduced seal failure, and cost-effectiveness. If you are looking for a reliable and efficient mechanical seal solution for your industrial application, consider using cartridge mechanical seals from SP PAC-SEAL SDN. BHD. With our superior design and performance, we can help you improve machine uptime, reduce maintenance costs, and achieve greater productivity.